The Future of Supply Chain Technology: How Predictive Analysis is Shaping Strategic Change

Fast forward to 2026, and it’s clear that the influence of artificial intelligence on supply chains is nothing short of transformative. Over half of supply chain leaders anticipate that AI will be steering all key decisions. This isn’t merely a tech prediction—it’s a sweeping overhaul of global commerce. As we face unprecedented volatility in capacity markets, energy supplies, and environmental factors, the real advantage lies in adapting swiftly rather than predicting expectations.

Geopolitical strains, sustainability goals, and digital revolutions have fused, creating ideal conditions for a technological transformation in supply chains. PwC’s 2025 Digital Trends study reveals that 80% of manufacturers are dedicating a solid portion of their improvement budgets to smart innovations, including automation, data analytics, sensors, and cloud solutions. This surge in investment highlights a truth: traditional, reactive approaches to supply chain management can’t keep up in this era of constant upheaval.

This in-depth analysis seeks to unveil how predictive analytics is reshaping supply chain dynamics, diving into the technologies, strategies, and outcomes charting the path for future logistics triumphs. From AI-driven demand predictions to digital replicas of supply chains, we will explore real-world applications and strategic impacts these innovations have on the future of logistics.

For supply chain leaders steering this transformation, the crossroads of technology and operational strategy are more significant than ever. The ensuing analysis offers a strategic framework and actionable insights to harness predictive analytics for competitive benefit in modern supply chain settings.

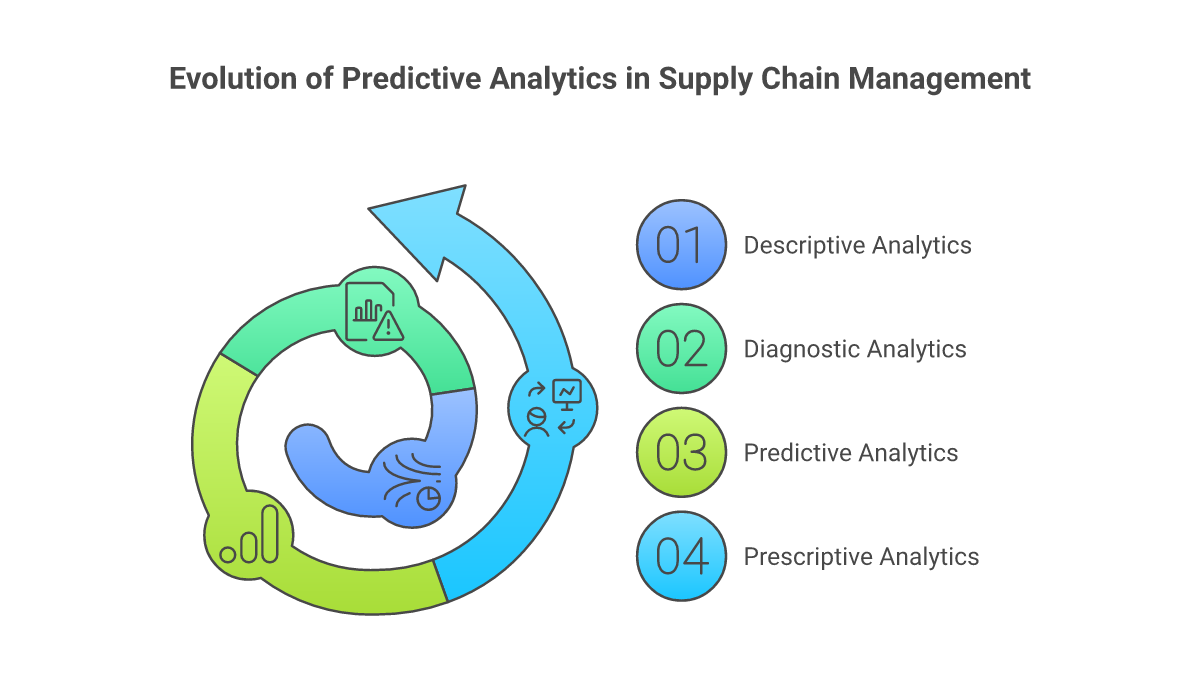

The Growth of Predictive Analytics in Supply Chain Management

Transitioning from descriptive to predictive analytics isn’t just a tech upgrade—it’s a fundamental change in decision-making within supply chains. In 2025, supply chain teams braced themselves for persistent challenges, from market capacities to energy availability. By the year’s end, it was clear that predictive analytics had evolved from niche tools to essential operations.

Deloitte’s 2025 Supply Chain Digital Transformation Survey reveals that businesses employing advanced predictive analytics saw a 42% drop in stockouts and trimmed excess inventory by 37%. These gains were driven by the ability to process volumes of data from sources like IoT sensors and market indicators to generate real-time insights.

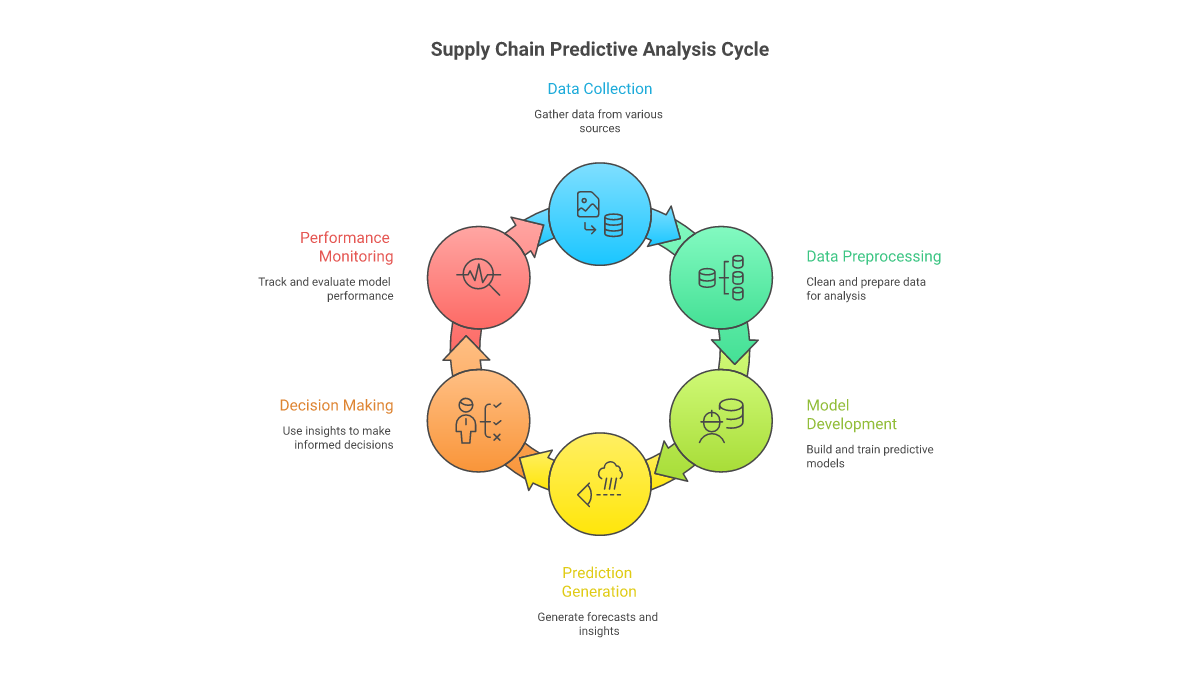

The technology enabling these capabilities has seen significant advancement. Today’s predictive platforms integrate machine learning algorithms that handle both structured and unstructured data, such as weather trends, social media buzz, and economic signals. This comprehensive method provides more precise and nuanced forecasts than traditional statistical models.

A key development is the democratization of predictive tools, accelerating their adoption. Once confined to specialized data teams, these tools are now accessible through easy-to-use interfaces, empowering broader organizational use and faster decision-making.

Beyond operational metrics, the impact is even felt in customer experience. Firms using predictive analytics report an 18% boost in customer satisfaction, thanks largely to reliable delivery times and pre-emptive issue management. This link between analytical prowess and enhanced customer interaction emphasizes the strategic value of predictive technology.

Critical Elements of Modern Supply Chain Predictive Analysis

Today’s effective supply chain predictive analysis depends on a complex network of interlinked technologies and techniques. ASCM’s 2026 Technology Outlook identifies five main components that must work together to produce actionable insights.

Firstly, data integration platforms lay the groundwork, pulling together information from varied sources like ERP systems, IoT devices, and market data. These platforms manage both structured and unstructured data, typically processing about 7.2 terabytes of supply chain data daily for a global manufacturer.

Next are the machine learning algorithms that form the core analytical engine, mining this data to uncover patterns and anticipate future results. Modern systems use ensemble learning methods, combining several algorithms to deliver prediction accuracy over 85% for short-term demands.

Then there’s digital twin technology, which creates virtual models of supply operations for scenario analysis and risk management. PwC’s research suggests that by 2026, 67% of Fortune 500 firms will have digital twins for essential supply chain elements.

The fourth element, automated decision support systems, turns analytical insights into practical advice. These systems typically cut decision latency by 65% compared to manual methods, while also enhancing decision quality by consistently applying best practices.

Lastly, visualization and reporting tools convert complex data into accessible insights for stakeholders. Modern setups automatically generate around 12 types of reports, ranging from operational metrics to strategic planning insights.

Managing Data Integration and Insights in Supply Chains

The key to successful predictive analysis lies in solid data integration and integrity management. According to Supply Chain Digital, firms focused on data quality management achieve a 43% boost in forecasting accuracy so compared to those with basic integration methods.

Successful strategies typically involve three core elements: automated data gathering, standardized data across systems, and ongoing quality checks. Leading organizations use scorecards to monitor data quality, tracking over 50 core metrics for accuracy and timeliness.

Gartner’s 2025 Supply Chain Technology Study highlights the need for monitoring and maintaining data quality across an average of 12 systems to achieve dependable predictive analytics. This spans ERP systems, transportation management systems, and external data sources.

Implementing Predictive Analytics: Strategies for a Resilient Supply Chain

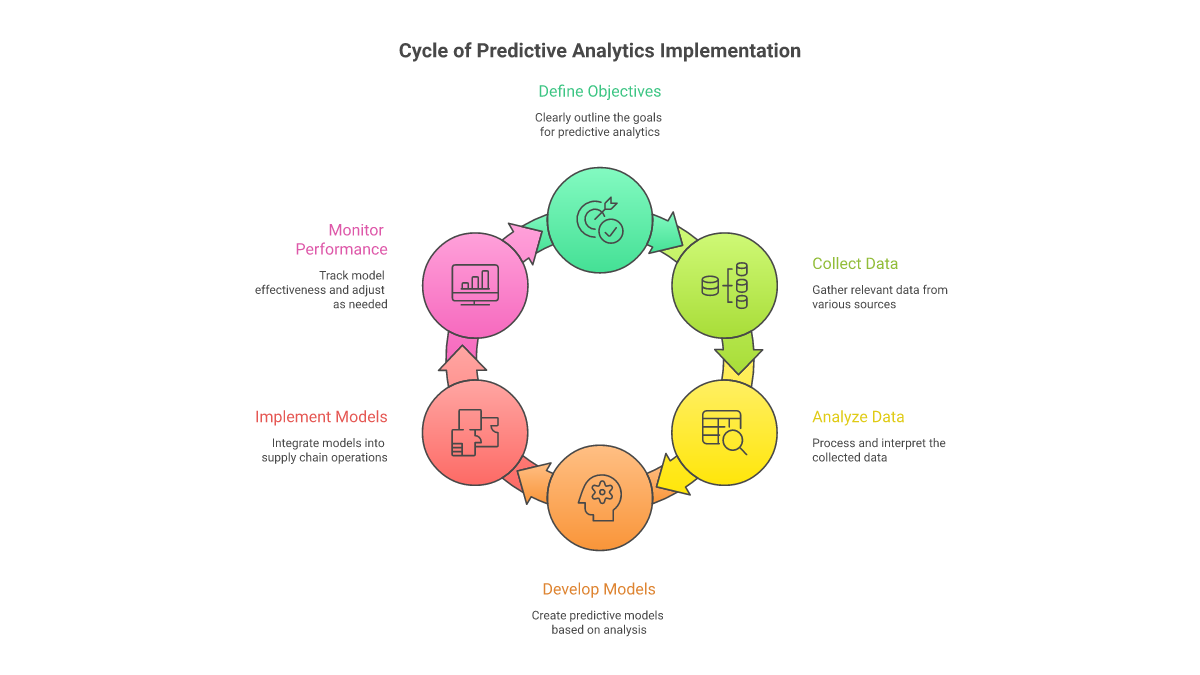

Introducing predictive analytics requires a well-coordinated strategy that balances tech capabilities with organizational preparedness. Deloitte’s 2026 Digital Transformation Roadmap suggests a three-phase implementation prioritizing quick wins and building towards full capabilities.

Phase one is all about laying a foundation, typically lasting 3-6 months. During this time, firms audit their data sources, establish quality protocols, and implement basic predictive models. Early adopters report a 22% bump in forecast accuracy even at this early stage.

The second phase focuses on expanding analytical prowess and embedding predictions into daily operations, spanning 6-12 months. Companies typically focus on 4-6 specific use cases, such as demand forecasting and inventory efficiency, with success rates soaring when concentrating on high-value scenarios.

Phase three, beginning 12-18 months in, aims at scaling and optimizing. Here, firms integrate predictive abilities fully into their operations, achieving a 47% cut in planning cycles and a 35% boost in working capital efficiency.

Crucial to success are clear governance and decision rights. Firms that specify roles for data management and decision-making show 58% higher satisfaction with their analytics implementations.

Change Management and Workforce Training

The human aspect of analytics deployment can be just as challenging as the technical. PwC’s 2025 Digital Transformation Survey suggests that 72% of failed projects cite poor change management as a root cause.

Successful firms invest 15-20% of their budget in training and change initiatives. This includes technical training on new tools and broader education on data-driven decision principles.

Top companies develop comprehensive programs covering technical proficiency with analytical tools, understanding of statistical concepts and their business applications, and effective use of insights in decision-making.

Measuring Success: Evaluating KPIs and Return on Investment

Assessing the impact of predictive analytics requires a robust measurement framework. ASCM’s 2026 Benchmarking Study suggests organizations track immediate operational wins and long-term strategic benefits.

Operational metrics often include improved forecast accuracy (on average 35%), reduced inventory (20-45%), and increased order fulfillment rates (15-25%). Leading firms also measure decision-making efficiency, often slashing planning cycle times by 40%.

Financial perks aren’t limited to direct cost savings. Companies report working capital improvements of 12% and reduced supply chain operating costs by 8-15% within 6-9 months.

Strategically, benefits are tougher to quantify but crucial. Firms report better supplier relationships, increased customer satisfaction (20-30% improvement), and a better response to market changes.

ROI considerations should factor in both tangible and intangible benefits. As Deloitte’s analysis shows, mature implementations see payback in 18-24 months, with ROI between 150% and 400% over three years.

Looking Ahead: Future Trends and Technologies

The pace of predictive analytics is quickening, driven by tech advances and evolving business needs. By 2026, several trends will shape supply chain analytics.

AI will increasingly take on routine decision-making, as Forbes reports, allowing humans to focus on strategic decisions. It’s expected that 63% of organizations will rely on AI for such roles.

Real-time analytics will benefit from edge computing, with industry forecasts suggesting 75% of supply chain data processed at the edge by 2026, enabling quicker responses.

Quantum computing will surface for certain complex optimizations, potentially improving accuracy by over 40% for specific scenarios.

Sustainability analytics will become integral, with organizations tracking and optimizing the environmental impact across 80% of their operations, advancing supply chain sustainability.

Conclusion

Shaping supply chains through predictive analytics offers both opportunity and necessity. Companies that master these capabilities enjoy notable advantages in efficiency, customer service, and strategic agility.

Success requires combining technical skill with change management. Investments should focus on tech and people, prioritizing results over tech for its own sake.

As we turn to 2026, mastering predictive analytics will distinguish supply chain leaders. Organizations must build these capabilities now to stay competitive in a data-driven world, ensuring effective transformation and risk management in logistics.