The Future of Supply Chain Management: Digital Transformation in 2026 and Beyond

Global investment in Digital Transformation will reach $3.4 trillion in 2026 ↗, with supply chain management modernization emerging as a top priority for companies everywhere. This massive investment signals a major shift from traditional linear models to dynamic, interconnected networks fueled by AI and automation. While 80% of companies already see greater resilience from their digital initiatives, the coming wave of transformation demands more than just resilience—it requires intelligence, speed, and security at new levels.

There’s never been a greater urgency for digital transformation in supply chain management. With geopolitical changes, evolving trade policies, and increasing cost pressures reshaping the global market, companies face a pivotal choice: embrace comprehensive digital transformation or risk being left behind. This isn’t just about rolling out new tech—it’s about wholly reimagining how supply chains function in a complex and connected world.

In this comprehensive look, we’ll explore how leading firms are using digital technologies to build supply chains that are more resilient, efficient, and intelligent. From AI-driven demand forecasting to blockchain-enabled transparency, we’ll check out the key technologies, strategies, and best practices that will define top-tier supply chain management in 2026 and beyond.

As we navigate these transformative changes, we’ll offer actionable insights and real-world examples of how companies are successfully employing digital solutions to tackle traditional supply chain challenges and secure sustainable competitive advantages in a rapidly changing market.

The Current State of Supply Chain Digital Transformation

According to fresh industry analysis, supply chain organizations are ramping up their digital transformation initiatives at an impressive pace. By 2026, 73% of supply chain leaders plan to have implemented advanced digital technologies ↗ across their operations, showing a big jump from 45% in 2024. This acceleration is driven by both external pressures and internal needs to boost efficiency and resilience.

The financial impact of this transformation is significant. Companies that have effectively implemented comprehensive digital supply chain solutions report cost reductions of 15-25% in operational expenses while achieving 20-30% improvements in inventory accuracy. These gains are particularly crucial in industries with intricate supply chains like manufacturing and retail, where even small improvements can equal millions in saved costs.

Patterns in technology adoption reveal a clear hierarchy of focus among supply chain leaders. AI and Machine Learning lead the investment focus with 65% of organizations planning major AI rollouts by 2026 ↗. Cloud-based supply chain platforms follow, with 58% of businesses prioritizing cloud migration to enable better visibility and collaboration across their networks.

Real-world data shows that companies taking a holistic approach to digital transformation achieve far better results than those opting for piecemeal solutions. Businesses that set up integrated digital platforms report 40% higher returns on investment compared to those using standalone solutions, underscoring the importance of strategic alignment in digital transformation efforts.

Yet, the path to digital transformation isn’t without its hurdles. Surveys indicate 62% of organizations cite data integration and quality issues as their biggest challenges, while 54% struggle with managing change and adapting their workforce to new technologies.

Key Technology Enablers for Supply Chain Efficiency

Leading the charge in supply chain digital transformation are key technologies that are radically changing how operations are managed and optimized. AI and Machine Learning are standout innovators, with applications ranging from demand forecasting to route planning and inventory management.

Advanced analytics and predictive modeling have become more sophisticated, allowing AI systems to process vast amounts of data and generate forecasts with 85-95% accuracy. This is a notable improvement over traditional methods, which typically hit accuracy rates of 60-75%.

The Internet of Things (IoT) and sensors are another backbone of digital supply chains, offering real-time monitoring and visibility. By 2026, the expected number of IoT devices in supply chain applications is 45 billion, providing a continuous flow of actionable data for optimization.

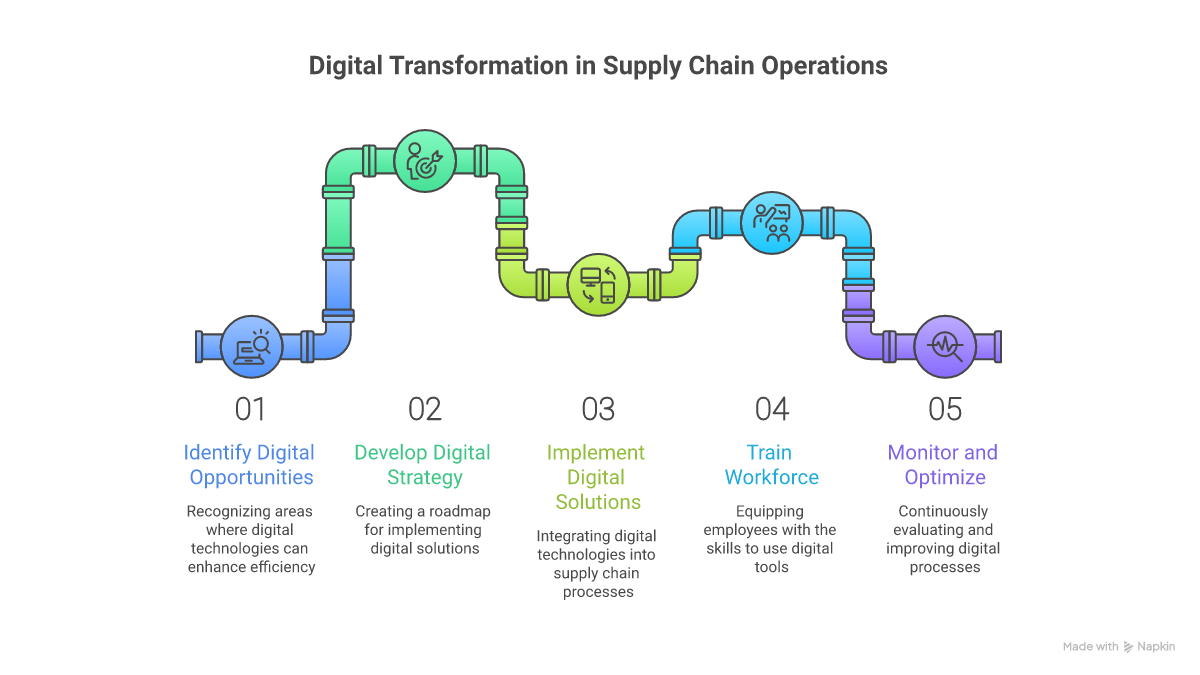

Transforming Supply Chain Operations Through Digital Innovation

Putting digital transformation into practice in supply chain operations is reshaping traditional processes in many ways. Companies at the forefront are seeing impressive results from strategically deploying digital technologies and data-driven decision-making.

Advanced analytics and machine learning algorithms are now capable of processing massive amounts of data to optimize inventory levels with unprecedented precision. Leading companies report inventory reductions of 20-30% while improving service levels by 15-20% using AI-driven demand forecasts and automated systems.

Digital twin technology is emerging as a transformative tool for optimizing supply chains. By creating virtual models of supply chain networks, companies can simulate scenarios and test strategies before implementing them. Those using digital twins report a 25% decrease in disruptions and a 30% boost in planning efficiency.

Automation technologies, especially in warehousing and logistics, are yielding significant operational benefits. Robotics and autonomous systems cut order processing times by up to 65% while boosting accuracy to 99.9%. These enhancements directly improve customer satisfaction and reduce operational costs.

Blockchain technology is tackling long-standing issues of transparency and traceability in supply chains. Companies using blockchain report 40% quicker supplier onboarding and a 50% drop in documentation processing time.

Process Automation and Workflow Optimization

Automating supply chain processes is crucial to digital transformation efforts. Advanced robotics and autonomous systems are revolutionizing warehouse operations, with technologies like automated guided vehicles (AGVs) and robotic picking systems becoming more common in modern distribution centers.

AI is pivotal in optimizing workflows, with machine learning algorithms analyzing operational data to pinpoint bottlenecks and suggest improvements. Firms using AI-driven workflow optimization report productivity gains of 25-35% across their supply chains.

Intelligent document processing (IDP) systems are transforming traditional paper-heavy processes, slashing manual data entry by up to 80% while increasing accuracy to 99%. This frees up supply chain professionals to focus on more strategic work.

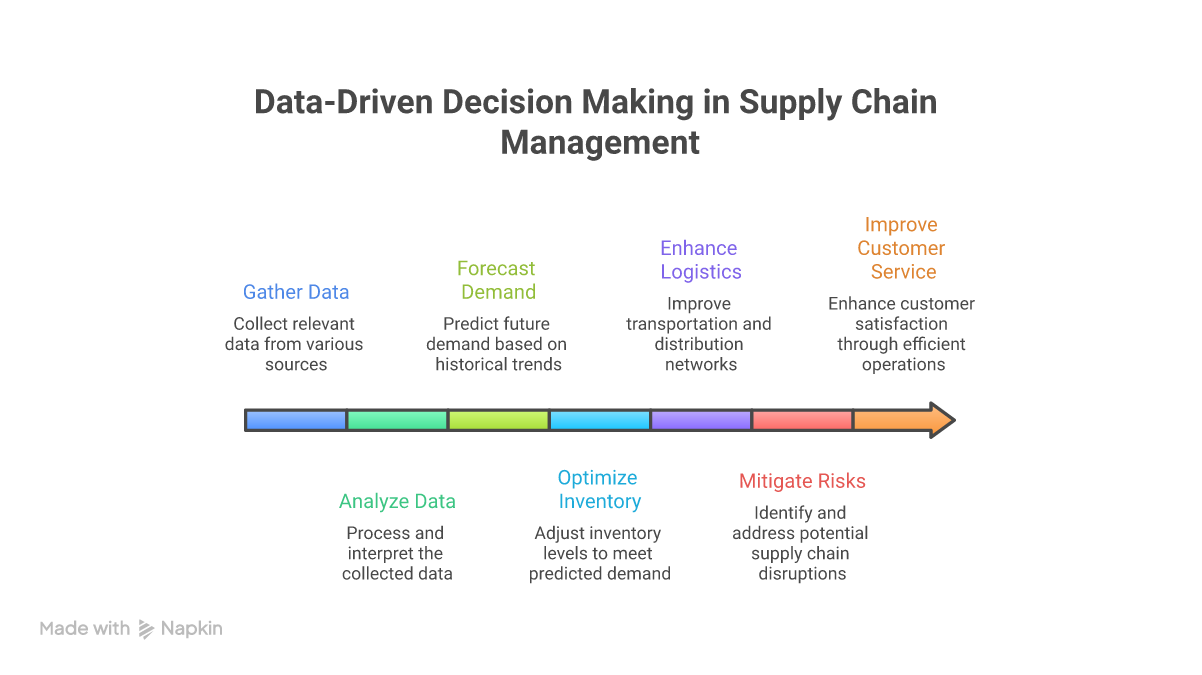

Data-Driven Decision Making in Supply Chain Management

The shift toward data-driven decision making marks a critical change in supply chain operations. Advanced analytics platforms are processing petabytes of data daily, providing insights that drive both strategic and tactical decisions across supply networks.

Predictive analytics tools have greatly advanced, enabling AI to forecast demand with over 90% accuracy across various time frames. This allows companies to optimize inventories and cut working capital needs by 15-25%.

Real-time analytics platforms offer unprecedented visibility into supply chain activities, enabling firms to identify and address disruptions in minutes rather than hours or days. Businesses using real-time analytics report a 40% drop in disruption impacts.

The integration of external data sources, such as weather patterns, social media trends, and economic indicators, supports more nuanced risk assessment and mitigation strategies. Organizations leveraging comprehensive data integration experience 30% fewer disruptions and 25% faster recovery times.

Machine learning algorithms optimize pricing and procurement decisions by analyzing market conditions and supplier performance. Companies adopting AI-enhanced procurement systems see cost savings of 10-15% on average.

Advanced Analytics and Predictive Modeling

The role of advanced analytics in supply chain management has evolved beyond basic reporting to include sophisticated predictive and prescriptive modeling. These tools enable firms to shift from reactive to proactive decision-making.

Machine learning models now consider numerous variables simultaneously to optimize routing and logistics, lowering transport costs by 15-20% while improving on-time delivery by 25%.

Cognitive analytics systems analyze unstructured data, such as social media and weather updates, to spot potential risks before they occur. Companies employing these systems report a 35% enhancement in risk identification and mitigation.

Building Resilient Supply Chain Networks

The emphasis on supply chain resilience has grown significantly, with companies investing heavily in technologies and strategies to build more adaptable and reliable networks. Digital transformation plays a vital role in this shift, enabling real-time visibility and swift response capabilities.

Network optimization technologies allow businesses to design more resilient supply chain configurations, with AI systems evaluating thousands of variables to find the best structures. Firms adopting these solutions report a 30% cut in vulnerability scores.

Improved risk management capabilities, enhanced by machine learning and predictive analytics, allow companies to identify and handle potential disruptions before they affect operations. AI-powered early warning systems detect risks on average 14 days sooner than traditional methods.

Supplier diversification, supported by advanced analytics, evaluates and monitors hundreds of suppliers across various risk areas. Companies leveraging these systems report a 40% drop in supplier-related disruptions.

Digital collaboration platforms promote tighter integration with key suppliers and partners, facilitating real-time information sharing and coordinated responses to disruptions. Firms with mature digital collaboration abilities respond to supply chain disruptions 45% faster.

Risk Management and Mitigation Strategies in Global Supply Chain Challenges

Implementing comprehensive risk management strategies is key in supply chain digital transformation. Advanced analytics and AI systems are deployed to identify, assess, and mitigate risks across networks.

Predictive risk analytics allow companies to foresee disruptions weeks or months ahead, enabling proactive strategies. Businesses using these tools cut disruption impact by 50%.

Automated risk monitoring systems continuously track risk indicators globally, issuing real-time alerts and actions when issues arise.

Future Trends and Emerging Technologies in Modern Supply Chain

Looking to 2026 and beyond, several emerging technologies promise to further revolutionize supply chain management. Quantum computing offers solutions for complex optimization issues beyond traditional computing capabilities.

Edge computing and 5G networks are boosting real-time processing, particularly in IoT applications, with firms reporting 60% faster response times and a 40% cut in data costs.

AI continues to advance, integrating natural language processing and computer vision for smarter automation and decision-making. Early adopters of these systems see 35-45% productivity jumps in key areas.

Blockchain technology is evolving past basic tracking to support new forms of collaboration and automation in supply chains. Smart contracts and DeFi streamline payment and documentation, cutting processing times by 90%.

Autonomous systems, like drones and self-driving vehicles, are growing more sophisticated, expected to play a bigger role in delivery and warehouse operations by 2026. Companies testing these report potential delivery cost cuts of 25-35%.

Innovation and Technology Adoption

Tech adoption in supply chain management is speeding up as businesses see digital transformation as crucial. Success demands a strategic approach to innovation and technology use.

Firms are adopting advanced methods for evaluating and deploying technology, with 72% now using formal innovation management processes. This structured approach leads to 35% higher success rates in transformation efforts.

Cross-functional collaboration and integration are becoming vital for successful technology adoption, with dedicated innovation teams blending technical, operational, and business expertise.

Conclusion

The digital transformation of supply chain management offers both unprecedented opportunities and necessary changes for modern enterprises. Looking forward to 2026 and beyond, the effective use of digital tech will increasingly define competitive success globally.

Companies must adopt a strategic and holistic approach to digital transformation, focusing on more than just technology but also redesigning supply chain processes. This involves investing in talent development, fostering innovation, and building strong digital partnerships.

The future of supply chain management will be defined by organizations that combine advanced tech, data-driven decision making, and adaptable operational models to create truly intelligent and resilient networks. The time to act is now, or risk falling behind as digital leaders surge ahead.