Mastering Supply Chain Optimization: The Key to Navigating Modern Management

Come 2026, the global supply chain optimization market is set to hit an astounding USD 10.2 billion, charting a remarkable CAGR of 8.2% ↗. Still, despite these optimistic projections, a staggering 63% of companies grapple with shortcomings in achieving their ideal supply chain efficiency. The chasm between potential and actual performance is more evident—and costly—than ever.

This year, supply chain authorities are facing challenges like never before. The blend of geopolitical strife, sustainability requirements, and tech upheaval has morphed once straightforward operations into a multifaceted, interconnected maze needing cutting-edge supply chain optimization tactics. And the rewards? Companies fine-tuning their supply chains boast profitability 15% above their peers according to key statistics ↗.

In this all-encompassing guide, we will uncover the core principles, budding technologies, and tried-and-tested strategies that shape modern-day supply chain optimization. From AI-enhanced demand forecasting to blockchain-facilitated transparency, we will explore how top industry players are overhauling their supply chains to secure a competitive edge in today’s ever-complex global market.

Regardless of whether you’re a veteran in supply chains or a newcomer, grasping these fundamental concepts is crucial for steering the future of logistics and operations management. Let’s dive into how you can overhaul your supply chain from just a cost center into a crucial strategic asset.

Grasping the Essentials of Supply Chain Management

At its essence, supply chain management covers the entire journey of goods, services, and data from raw material providers down to the final consumers. Fast forward to 2026, and this once-simple process is now a complex web far exceeding mere logistics management. Based on the latest ASCM insights, a significant 78% of organizations now view their supply chain as a strategic function, rather than a mere operational must-have.

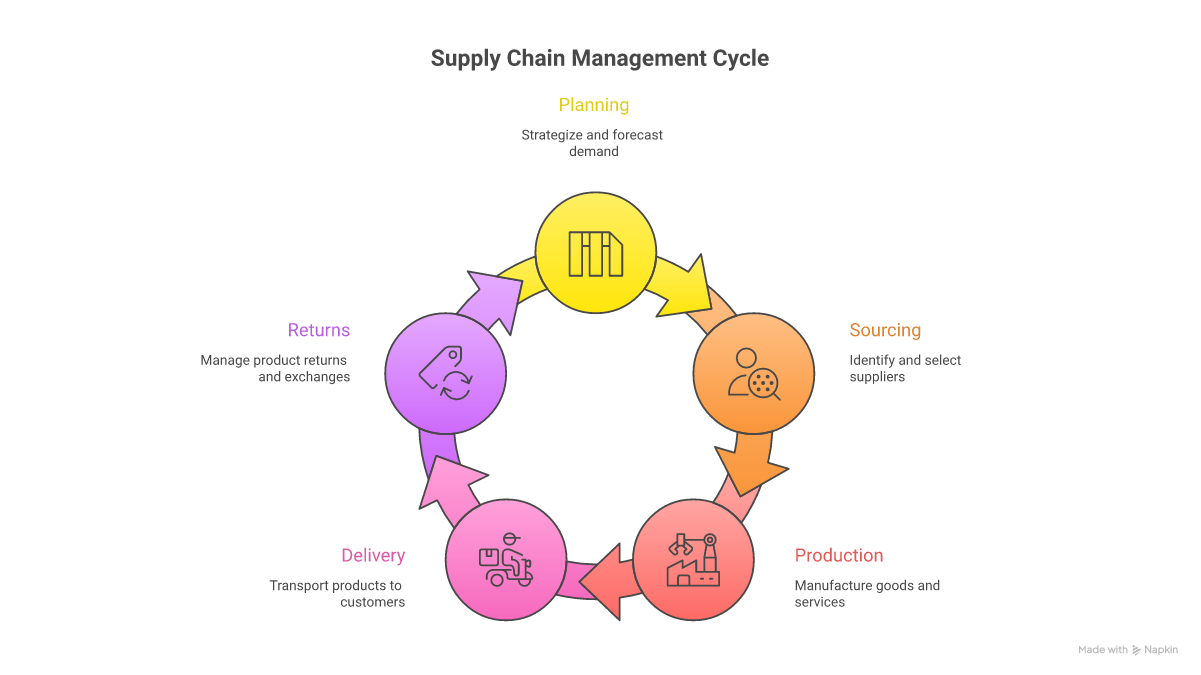

Today’s supply chain managers need to master five critical components: planning, sourcing, manufacturing, delivery, and returns. Each part needs individual optimization while ensuring seamless integration with the others. The complexity is daunting—one typical global manufacturer might juggle dealings with over 200 direct suppliers and countless indirect ones.

Insights from the Global Supply Chain Report indicate that businesses with mature supply chain setups boast 25% higher inventory turnover and 20% better order fulfillment rates. These gains are evident on the balance sheet, with optimized supply chains delivering EBITDA margins 7.5% above industry norms.

Let’s consider TechCorp, a top electronics manufacturer, which recently revitalized its supply chain fundamentals. By integrating advanced planning solutions and reshaping supplier ties, they managed to slash inventory holding expenses by 32% and enhance their on-time delivery from 82% to a stellar 97%.

The secret to such transformation is recognizing that supply chain optimization is not just a one-off project but a continuous journey of improvement. Companies need to routinely evaluate their strengths across various areas, from tech infrastructure to skillsets.

Modern Inventory Management: Strategic Approaches and Practices

In 2026, adept inventory handling has emerged as a critical distinction in supply chain success. Research from the Supply Chain Analytics Institute suggests that excessive inventory locks up about $1.1 trillion in working capital worldwide, while stockouts cause retailers to forfeit nearly $984 billion in lost sales annually.

Contemporary inventory optimization now harnesses AI and machine learning to balance these clashing demands. Leading businesses use predictive analytics to project demand with accuracy levels surpassing 85%, a vast leap from the 65% accuracy that traditional methods typically reach.

Dynamic safety stock computations have revamped the landscape of inventory planning. Shying away from rigid parameters, today’s systems adapt stock levels in real-time, factoring in variables like lead time variance, demand shifts, and supply risks. Businesses employing these strategies report average inventory dips of 25-30% while preserving or boosting service rates.

The Just-in-Time inventory system has transformed into what’s now termed “Right-Time” inventory management. This fresh perspective acknowledges that varying products and markets demand distinct inventory tactics. For effortless consumer goods, traditional JIT methods might still apply, while buffer stock strategies are vital for crucial components in regulated sectors.

Take Global Pharma Co. as a case in point. They revolutionized their inventory management by segmenting their products based on demand trends and criticality. Tailoring their inventory approach let them cut total inventory by 18% while boosting service levels for essential medications from 94% to an impressive 99.2%.

Techniques for Optimizing Logistics and Transportation

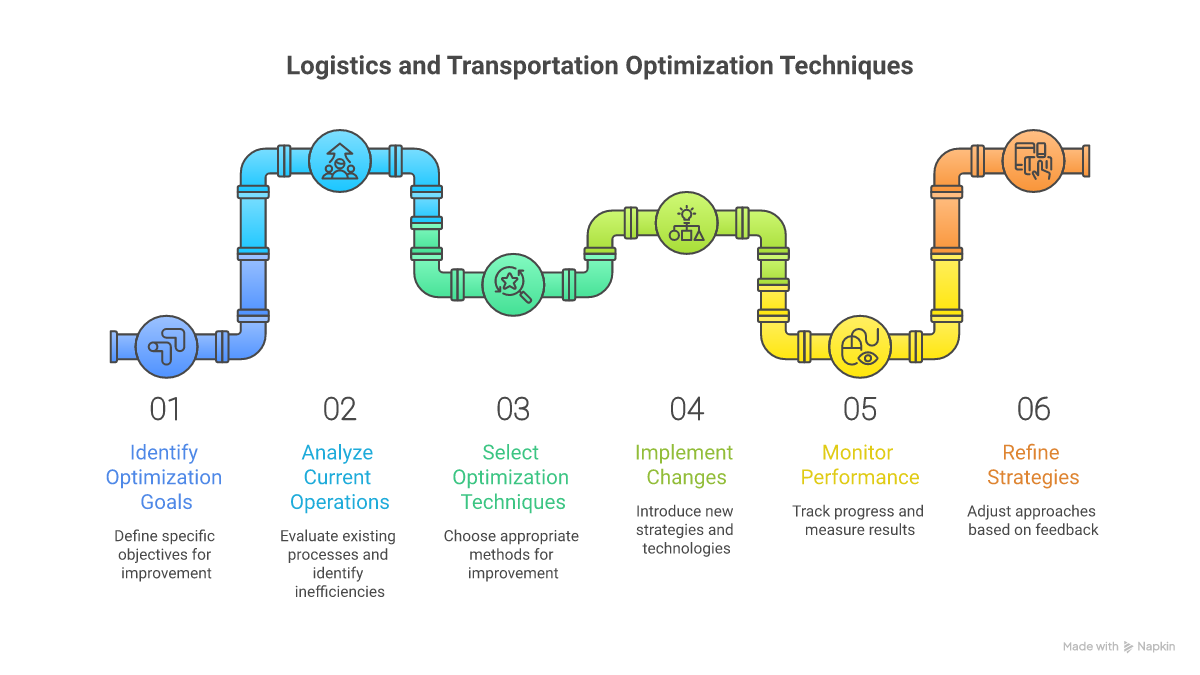

The transportation sector is on the brink of one of its most significant overhauls in decades. With global logistical costs predicted to surge to $15.7 trillion by 2026, companies are pushing the envelope by adopting state-of-the-art technologies to finesse their transportation frameworks. Real-time tracking and dynamic routing systems have become standard practice, offering unmatched visibility and control.

Autonomous trucks and drone deliveries are no longer sci-fi but operational realities. Key logistics firms report that autonomous vehicles now tackle 15% of long-haul routes in optimal conditions, delivering 22% cost savings ↗ and a 31% gain in delivery regularity. The transformation in last-mile delivery is just as impressive, with drones slashing costs by up to 70% in fitting urban areas.

Multimodal optimization has emerged as a pivotal tactic for robust transportation networks. Businesses routinely analyze millions of routing scenarios across different transport modes to strike the best compromise between cost, speed, and reliability. Advanced algorithms consider elements like weather conditions, traffic updates, and port congestion in real time.

LogiTech Solutions shines as a testament to the strength of modern transportation optimization. By integrating AI-guided route optimization and live load consolidation, they cut empty miles by 28% while boosting on-time delivery by 24%. Plus, their carbon emissions went down by 35%, underscoring the environmental perks of fine-tuned logistics.

Cross-docking setups have taken significant strides, with automated centers processing shipments up to four times faster than the old methods. These hubs use computer vision and robotics to sort and direct packages with minimal human oversight, trimming handling costs by up to 65%.

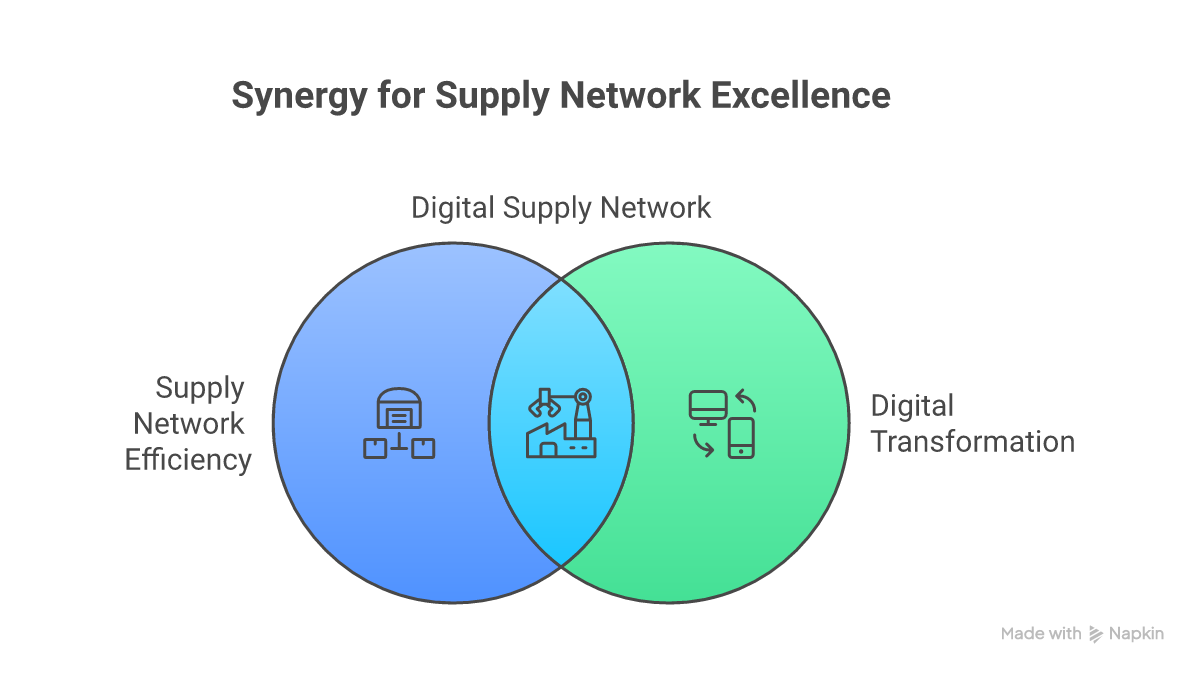

Boosting Supply Network Efficiency Through Digital Transformation

Digital transformation stands as the bedrock of supply chain optimization as we reach 2026. Recent analysis underscores that companies investing in digital supply chain initiatives see 7.5% higher revenue growth and 5.8% higher EBITDA margins compared to their digital-sluggish counterparts.

Cloud-based supply platforms are now synonymous with modern operations. These platforms offer a live view of the entire supply chain, paving the way for quicker decision-making and more efficient collaboration. Firms using these systems report average cuts in order-to-delivery cycles by 35%.

Blockchain has transitioned from trial runs to a crucial tool for supply chain transparency and traceability. Leading retailers now track more than 65% of their high-value items via blockchain, which has led to a 43% drop in counterfeit products and a 28% uptick in recall efficacy.

The Internet of Things (IoT) has redefined how companies oversee and handle their supply networks. With an expected 75 billion connected devices globally by 2026, firms are harnessing IoT data to enhance everything from warehouse tasks to fleet management. Intelligent sensors offer real-time condition assessments, enabling predictive maintenance and slashing equipment downtime by up to 45%.

Consider AutoParts Global’s shift, which embraced a full-scale digital supply network platform. By linking their entire network of suppliers, producers, and distributors, they slashed lead times by 40%, improved forecasting accuracy to 92%, and trimmed operational costs by 23%.

Utilizing Supply Chain Analytics and Decision Intelligence for Risk Management

Advanced analytics and AI have dramatically overhauled supply chain decision-making. By 2026, more than 75% of large enterprises will count on AI-powered supply chain applications, generating $2.9 trillion in business value each year, as projected by industry leaders.

Predictive analytics now extend far beyond simple demand forecasting to include risk prediction, maintenance scheduling, and supplier performance enhancement. Organizations utilizing these tools face 35% fewer disruptions and manage responses to supply chain issues 42% faster.

Digital twins are indispensable for supply chain optimization. These digital replicas of physical supply chains allow businesses to simulate different scenarios, optimizing operations without risk. Companies using digital twins experience 28% fewer stockouts and 25% lower logistics expenses.

Machine learning algorithms constantly dissect vast data streams to uncover patterns and anomalies that might escape human notice. For instance, leading retailers utilize ML-powered systems for store-level inventory optimization with 94% precision, trimming waste by 35% and enhancing product availability.

Take PrecisionManufacturing Corp as an example, illustrating the prowess of advanced analytics. By adopting a broad-spectrum analytics platform, they achieved a 45% reduction in production planning time, cut inventory costs by 30%, and boosted customer satisfaction scores by 25%.

Global Supply Chain Trends and Visions of the Future

As we peer into 2027 and beyond, a series of pivotal trends is redefining the trajectory of supply chain optimization. Sustainability has evolved from a preferable option to a vital business need, with 82% of firms now factoring environmental impacts into their supply chain decisions.

Nearshoring and friendshoring continue to gain traction as businesses adjust to prioritize supply chain resiliency over mere cost-cutting. New statistics show that 45% of multinational entities have proactively diversified their supplier bases across various regions, with approximately 35% of previously offshore production being reallocated closer to key markets.

The rise of autonomous supply chains marks the next milestone in optimization. These self-regulating, autonomous systems harness advanced AI to make real-time decisions sans human direction. Early adopters report efficiency boosts of up to 50% in standard operations.

The fusion of 5G and edge computing is ushering in unparalleled levels of supply chain transparency and control. With ultra-low latency and vast device connectivity, companies now have real-time monitoring and optimization capabilities across global networks.

Circular supply chains are becoming increasingly common as businesses tackle environmental challenges and adhere to regulatory demands. Leaders in this domain benefit from 40% lower material costs while slashing their carbon footprint by up to 50%.

Wrapping It Up: The Future of Supply Chain Optimization

Supply chain optimization has shifted from being a simple cost-saving exercise to a strategic necessity that seeds competitive advantage. The organizations that will thrive in 2026 and onward are those seamlessly weaving advanced tech, sustainable strategies, and innovative management into their supply chain operations.

As discussed throughout this detailed guide, the key to thriving lies in adopting a holistic optimization approach—one that factors in not just efficiency and expenses but also resilience, sustainability, and adaptability. The tools and methods shared here offer a blueprint for achieving these aims.

For supply chain executives, the road is clear: adopt digital transformation, enhance your analytics capabilities, and build flexible, resilient networks that can shift with the market. The future of supply chain optimization isn’t just about doing things better—it’s about doing better things.