Logistics Trends 2025: Transforming Supply Chains Through Digital Innovation and Sustainability

By 2025, the global logistics market is set to hit $12.8 trillion ↗, marking a pivotal moment in the evolution of supply chains. But beneath the surface of this astounding figure is a more compelling narrative: companies embracing digital transformation have reported 23% higher operational efficiency ↗ than those lagging behind. This striking difference not only indicates market growth but suggests a fundamental rethinking of how goods flow across the global economy.

The merging of artificial intelligence, automation, and sustainability initiatives is presenting unique opportunities and hurdles for logistics operators worldwide. As per DHL’s recent Logistics Trend Radar, 76% of companies are ramping up their tech investments to stay ahead, while 82% have named sustainability as a top strategic priority. This dual focus on innovation and environmental responsibility is reshaping everything from warehouse operations to the last-mile delivery process.

In this in-depth analysis, we’ll explore how cutting-edge technologies, shifting consumer expectations, and environmental demands are revolutionizing logistics operations. From AI-enhanced inventory management to eco-friendly fleet initiatives, we’ll examine the prominent logistics trends of 2025 that are set to shape success, providing practical insights for entities navigating this swiftly changing industry.

The stakes are high: McKinsey research shows that leaders in digital logistics adoption are cutting costs by 15-25% while boosting service levels by up to 30%. As we investigate each trend, we won’t just focus on the technologies but also delve into strategic implications and implementation challenges, identifying what will set market leaders apart in the coming years.

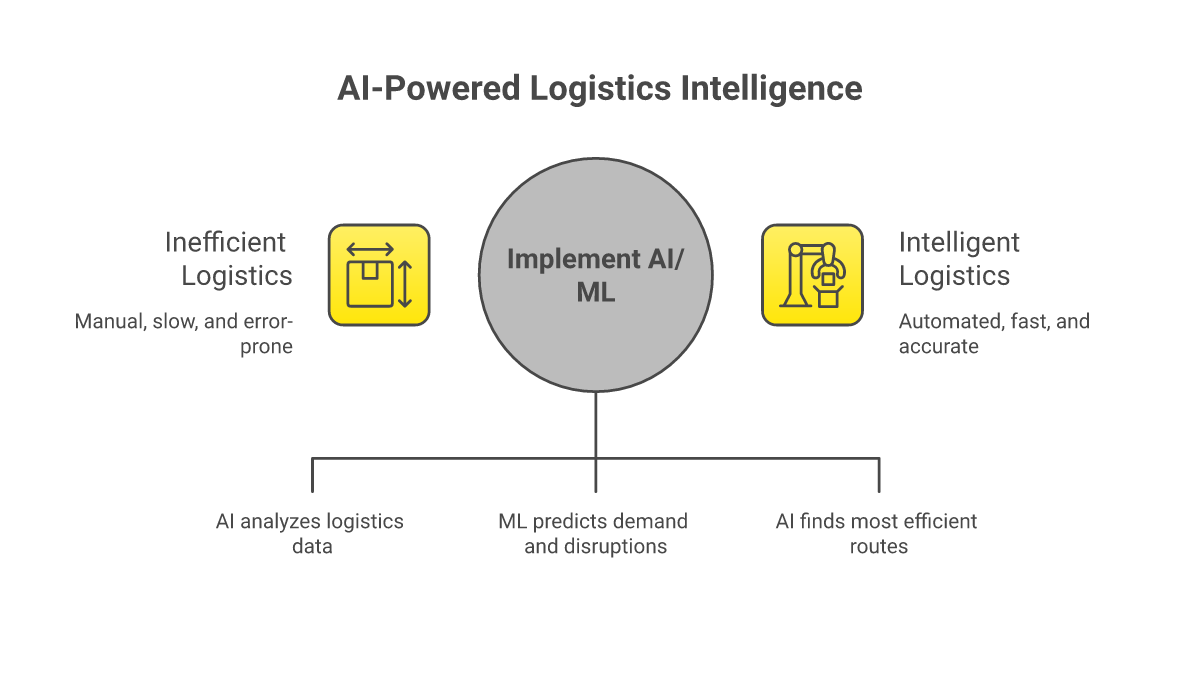

AI and Machine Learning: The New Logistics Intelligence

Artificial intelligence is the bedrock of logistics evolution heading into 2025, with expectations for the AI logistics market to spring to $14.3 billion globally. This marks a shift from AI being just a rising technology to an essential operational backbone. Gartner studies suggest that by 2025, 75% of large companies will have integrated AI into their supply chain operations, a significant rise from 32% in 2023.

AI is making a major impact, especially in predictive analytics and demand forecasting. Top logistics firms report a 35-45% boost in forecast accuracy thanks to AI, leading to inventory cost cuts of 20-30%. Consider DHL’s use of AI-driven demand forecasting across Europe, processing over 200 variables in real-time—from weather trends to social media chatter—achieving 95% forecast accuracy, a 40% jump compared to traditional methods.

Route optimization is another key AI application with concrete results. UPS’s ORION system, fortified with machine learning in 2024, saves the company $400 million annually and cuts delivery vehicle emissions by 100,000 metric tons. The system manages 30,000 route optimizations per minute, factoring in traffic patterns and package sizes.

In warehouse operations, AI brings significant efficiencies through smart automation. Amazon’s latest AI-equipped fulfillment centers show a 65% increase in throughput over traditional setups while slashing picking errors by 75%. The system orchestrates hundreds of autonomous mobile robots (AMRs) in real-time, adapting to demand shifts in minutes, not hours.

AI’s predictive powers are also enhancing risk management and supply chain resilience. Munich Re’s 2024 report reveals that companies using AI for risk prediction see 42% fewer disruptions and recover 60% faster from incidents, a significant edge in an era of increasing supply chain volatility.

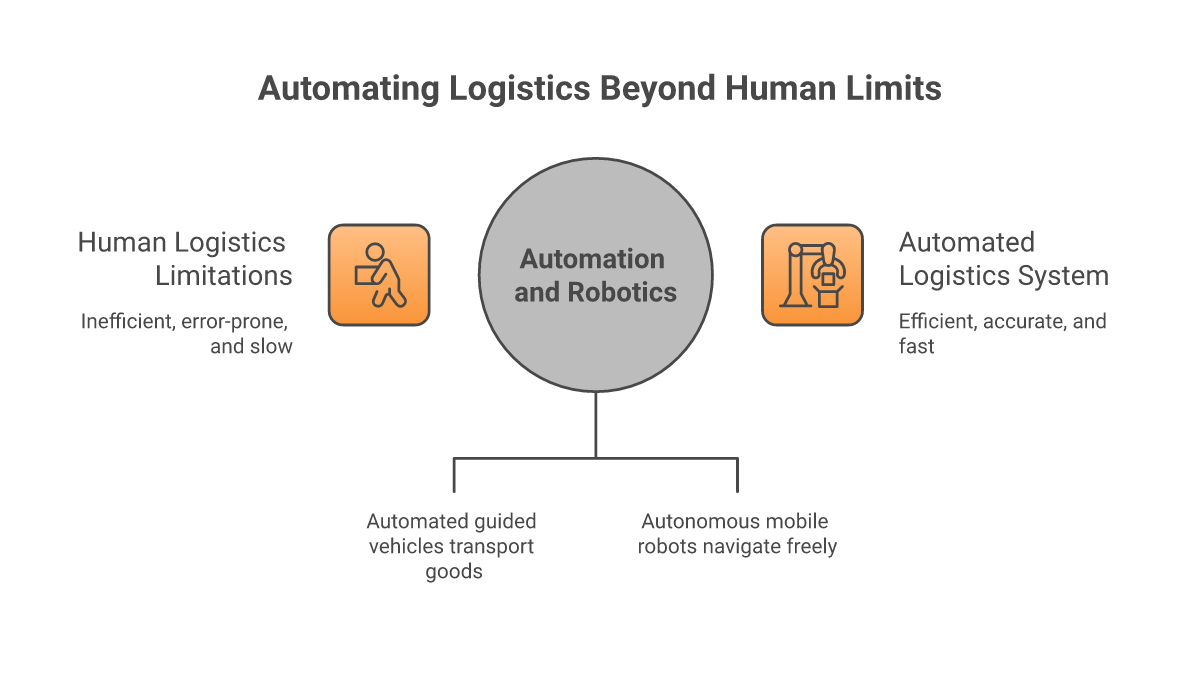

Automation and Robotics: Beyond Human Limitations in the Future of Logistics

The warehouse automation market is estimated to hit $41 billion by 2025 ↗, propelled by labor shortages and rising efficiency demands. The International Federation of Robotics reports a 63% rise in logistics robot installations in 2024, marking the fastest growth rate for industrial robot applications.

Leading this shift are automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), with worldwide deployments expected to exceed 500,000 units by 2025. Walmart’s recent AMR rollout across 25 distribution centers boosted throughput by 30% while slashing operating costs by 20%, confirming the scalability of automation.

Picking and sorting automation showcases particularly impressive advances. Today’s robotic systems can achieve 600-1,000 picks per hour—triple what a human can do—while maintaining 99.9% accuracy. DHL’s adoption of robotic picking across Europe has cut labor costs by 40% and sped up order fulfillment by 50%.

Automated storage and retrieval systems (AS/RS) are another game-changer, with the market expected to weigh in at $9.18 billion by 2025. These systems optimize warehouse space by up to 85% and cut picking times by 60%. Target’s implementation of AS/RS in its regional distribution centers increased storage density by 40% and halved order processing times.

Perhaps most notably, automation supports 24/7 operations free of human shift constraints. Ocado’s fully automated warehouses operate nonstop, handling 65,000 orders daily with 99.9% accuracy—performance that just isn’t possible using traditional labor models.

Sustainable Logistics: The Green Imperative

Environmental sustainability isn’t just an extra anymore; it’s a core business goal, with 78% of logistics firms naming sustainability as a top priority for 2025. Considering that the industry is responsible for 11% of global emissions, there’s increasing pressure from both regulators and customers to change.

Electric vehicles are leading the charge in sustainability, with major logistics firms pledging 100% electric last-mile delivery fleets by 2030. FedEx’s move to electric vehicles in urban areas already cut emissions by 40% and operating costs by 25% through reduced maintenance and fuel expenses.

Eco-friendly warehouses are showing equally impressive progress. Utilizing solar power, LED lighting, and smart energy systems has lowered facility operating costs by 30-40% and cut carbon emissions by up to 50%. Amazon’s climate pledge-aligned fulfillment centers now function on 100% renewable energy, setting a new industry benchmark.

Optimizing packaging is another key sustainability area. Research shows better packaging design can cut material usage by 25-35% and improve loading efficiency by 15-20%. DHL’s AI-optimized packaging solutions have reduced material waste by 40% and enhanced vehicle space utilization by 30%.

Circular logistics is gaining ground as companies see both environmental and economic benefits. Automated sorting and AI-driven processing now allows reverse logistics to recover 80% of returned materials for reuse or recycling, up from 45% in 2023.

Alternative Fuel Solutions for Sustainable Supply Chains

Beyond electric vehicles, logistics operators are exploring various sustainable fuel alternatives. Hydrogen fuel cell technology holds great promise for heavy-duty transport, with pilots showing over 500-mile ranges while generating no emissions. Major manufacturers like Volvo and Daimler are committed to producing hydrogen-powered trucks by 2025.

Sustainable aviation fuel (SAF) is emerging as a crucial solution for air freight, with primary carriers pledging 10% SAF usage by 2025. While more expensive than conventional jet fuel at present, scaling production is expected to make SAF affordable by 2027, paving the way for widespread adoption.

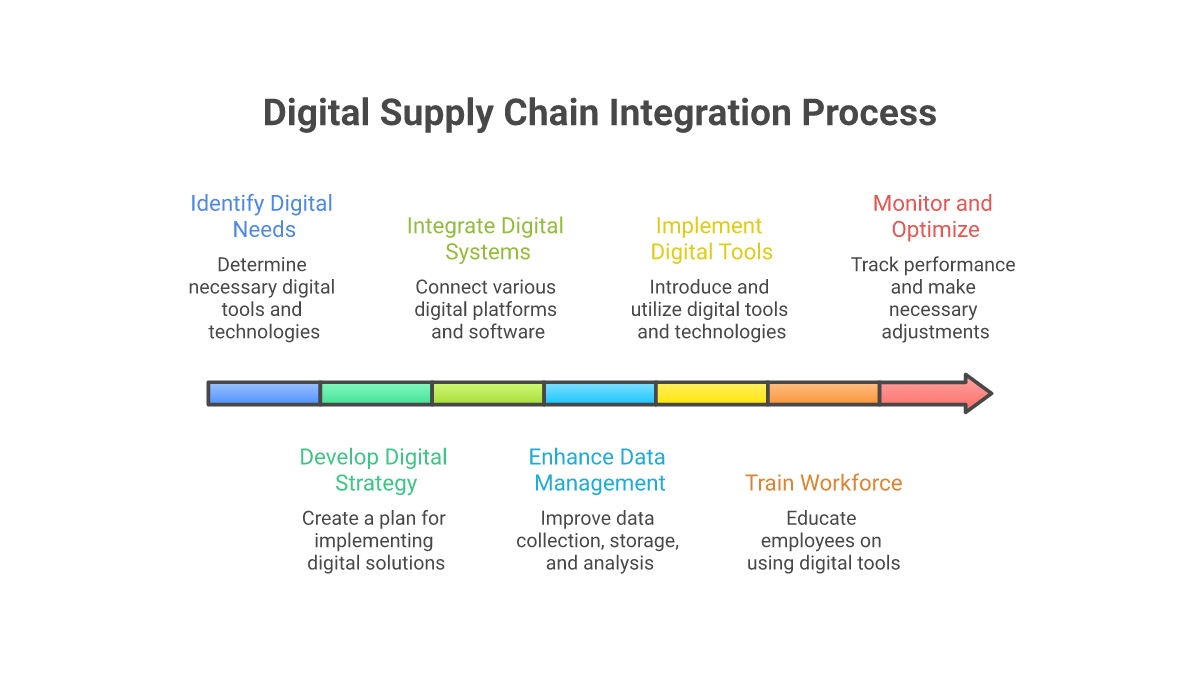

Digital Supply Chain Integration

Digitization is accelerating, with 85% of companies planning major digital investments through 2025. The integration of Internet of Things (IoT) sensors, blockchain, and cloud-based platforms offers unprecedented visibility and control across supply chains.

IoT deployment in logistics is projected to hit 50 billion connected devices by 2025, providing real-time data from vehicle locations to cargo conditions. Maersk’s use of IoT-enabled containers has improved cargo monitoring accuracy by 99% and reduced insurance claims by 40%.

Blockchain technology allows for end-to-end transparency in supply chains, with 65% of logistics firms planning blockchain implementation by 2025. Walmart’s blockchain food traceability initiative cut trace time from seven days to 2.2 seconds, greatly enhancing food safety and cutting waste.

Cloud-based transportation management systems (TMS) are emerging as essential integration platforms. Modern TMS solutions yield an average ROI of 7.5% of freight spend, with some users saving up to 12%. Real-time optimization of multi-carrier networks leads to significant efficiency gains.

APIs and microservices architecture enable seamless integration between systems and partners. Companies report 60% quicker partner onboarding and a 40% cut in integration costs through modern API approaches compared to traditional EDI methods.

Data Analytics and Visibility

Advanced analytics convert raw data into actionable insights. Leveraging predictive analytics, companies see a 25-30% reduction in inventory carrying costs while boosting service levels by 20-25%. Real-time visibility platforms provide unprecedented insight into shipment status and disruptions.

Control towers have evolved from simple visibility tools to AI-powered decision aids. Modern platforms process millions of events daily, spotting disruptions and responding before they impact operations. Early adopters report a 35% drop in supply chain exceptions and 45% faster response times.

Last-Mile Innovation

The last mile, accounting for up to 41% of total supply chain costs, is seeing innovative leaps through 2025. Autonomous delivery vehicles, including sidewalk robots and delivery drones, are transitioning from pilot programs to mainstream use in cities.

Micro-fulfillment centers are spreading in urban locations, with the market predicted to reach $5.3 billion by 2025. These centers cut delivery distances by 50-70% and enable 30-minute windows for essentials. Target’s urban strategy has reduced delivery costs by 90% compared to regional shipping.

Crowdsourced delivery platforms are expanding fast, with expectations to hit a $12.9 billion market by 2025. These platforms offer delivery flexibility and cut fixed costs, though companies must manage quality and reliability issues carefully.

The role of smart lockers and alternative delivery points is expanding, with installations expected to grow by 300% by 2025. These solutions cut failed deliveries by 70-80% and reduce last-mile costs by 35% compared to home delivery.

AI-driven real-time route optimization is cutting delivery times by 20-30% and improving vehicle utilization by 15-25%. Adjustments based on traffic, weather, and demand optimize delivery efficiency.

Customer Experience Enhancement

Innovation in the last-mile sector is increasingly focused on customer experience, with 82% of companies considering it a key differentiator. Real-time tracking, precise delivery windows, and flexible options are now expected rather than extra features.

Mobile apps and chatbots give customers more control over their deliveries, with 75% expecting real-time updates and modification options by 2025. Companies that meet these expectations report 30% higher customer satisfaction scores.

Conclusion

The logistics industry stands at a crossroads where technology adoption, sustainability imperatives, and evolving customer expectations come together, presenting both unprecedented challenges and opportunities. Success in 2025 and beyond won’t just come from implementing individual technologies but from harmonizing them into coherent, customer-centered solutions.

Organizations must focus on digital transformation while keeping sustainability objectives front of mind. The most successful companies will use AI and automation to boost efficiency and cut environmental impacts, while also meeting increasingly demanding customer expectations for speed and transparency.

As we look towards 2025, the road ahead is clear: invest in digital capacities, embrace sustainable approaches, and maintain a steadfast focus on customer experience. The future of logistics belongs to organizations that can integrate these elements while adapting to rapid market changes, all while implementing strategic warehouse automation trends that propel supply chain transformation.